Stairs and Railings

Stairs and Railings

Every commercial building inspector is trying to climb the stairs to success but not all stairs have the same levels of protection. Like so many other systems present in a building, stairs too have certain set standards that have to be present. It is through these standards that a building can maintain a level of safety for its occupants and building owners.

Sprinkled throughout the International Standards of Practice for Commercial Property Inspections (ComSOP) are references and requirements for a commercial building inspector to follow. These include sections:

6.5.2 Exterior

- all exterior doors, decks, stoops, steps, stairs, porches, railings, eaves, soffits and fascia;

6.5.11 Doors, Windows and Interior

- inspect the walls, ceilings, steps, stairways and railings; D. inspect interior steps, stairs and railings;

6.5.12 Life Safety

- inspect exit stairwell handrails;

Basic Stair Design

The basic stair design or configuration is a stair stairwell or stairway where each tread is a minimum of 10 inches deep with a maximum riser height of 7 ¾ inches and a minimum of 4 inches but at no point can there be more than ⅜ of a inch difference in that stair run. These numbers and measurements have to be exact because any variance between one step and another could be a trip hazard.

The proper clearance of headroom must also be present. Measuring from a plane parallel and tangent to the stair tread nosing, a height of 6 feet eight inches must be present throughout the entire stairwell.

Exceptions might be present when dealing with circular or curved stairways as well as ladderways that service very vertical locations.

Hand and Guard Railings

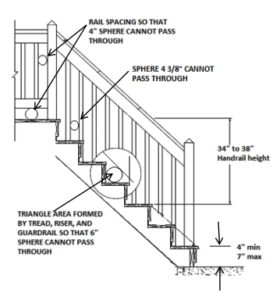

A graspable hand railing is required whenever there are four or more risers present. Any total rise higher than 30 inches requires a guardrail. If 30 inches was divided by a 7 inch rise then there would be at least 4 stairs required and 4 stairs requiring a handrail. Some might argue that whenever there are two or more risers a hand railing should be present. Regardless of what standard or code is being used, hand railings can be installed between 34 and 38 inches above the tread. This is consistent with stairs, ramps and protected walking surfaces.

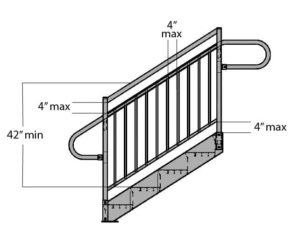

If a hand railing is to be placed 34 – 38 inches above a tread a guardrail has to be present to protect the open side of a stair and it should be at least 42 inches above the tread. This is typically why a hand railing is placed on the side of a guard railing instead of the other way around. When creating the guard railing, at no point should there be any vertical or horizontal openings larger than what a 4 inch sphere can fit through. The design or installation of a guardrail should never create a climbable or ladder effect surface. These design elements should always be noted.

The triangle shape created when the tread and riser meet the guard rail cannot be larger than what a 6 inch sphere can fit through. The only exception is when the elevated walk surface is for access to electrical, mechanical or plumbing systems and in areas that are not open to the public. At that point openings should not allow passage of a sphere that is 21 inches in diameter.

When looking at a graspable hand railing that has been properly placed 34 to 38 inches above the tread it must also be secure, and have at least 1 ½ inches of clearance between the wall or guardrail and the handrail. A pinch point is created whenever the 1 ½ inches becomes smaller. The diameter of the graspable railing must be between 1 ¼ and 2 inches. Anything larger than 2 inches could be difficult to grasp. All hand railings must be continuous as well. Breaks in handrailing can exist at landings or direction change but not in the middle of the stair run.

The maximum width of a stairwell being serviced by only one railing on one side is four feet. If a stairwell is wider than 4 feet a railing must be present on both sides. The width of the stairwell might be predicated on design characteristics or esthetics or also by occupancy. The width of the stairwell is calculated by multiplying the floor’s occupancy load by 0.3. Or in other words there must be at least 0.3 inches of stair per person with a minimum of 44 inches.

[ Width = 0.3 x floor’s occupant load]

The inspector is not required to perform this calculation but it is good practice to keep it in mind and to look for any bottlenecks that might exist in the exit or egress plan of the building.

The installation of the handrailing should also include returns to the wall or terminations to newel posts. A hand railing left with the end open can be a catch hazard. Exceptions to this would be if a railing was designed to be ADA (Americans with Disabilities Act) compliant. This type of design has several other requirements.

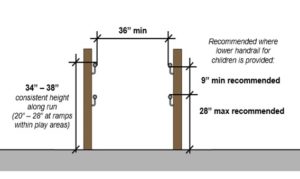

If a stairwell or ramp is built to be ADA compliant there will be a hand railing on each side of the stairwell or ramp. In certain situations a lower set of hand railings are placed 9 inches below the standard height of 34 – 38 inches or a maximum of 28 inches from the bottom. This will accommodate children or persons in wheelchairs. The stairwell or ramp must also be at least 36 inches wide.

Hand Railings designed for ADA use must also have extensions of at least 12 inches at the top and bottoms of the stairs or ramps. These must be located in the same direction of travel as the stairs or ramp and be a continuous gripping surface without obstruction up to 20% of the length. This is to accommodate for structure and support. The only exception to the extension or direction of travel is for switchbacks at landings. The purpose of these extensions is to provide for stability as well as directional guidance for the visually impaired.

Inspecting Stairs and Railings

The inspector should make a point to walk every stair and ramp area.. All issues or observations should be noted in the report. The ComSOP clearly defines the extent to which this must be performed. The inspector is not required to perform any calculations or take any measurements but understanding the standards will guide the inspector through the process and provide the client with necessary information.